visionpro案例: 轴承缺珠检测

visionpro案例: 轴承缺珠检测

- 项目概述

- 思路以及解题过程

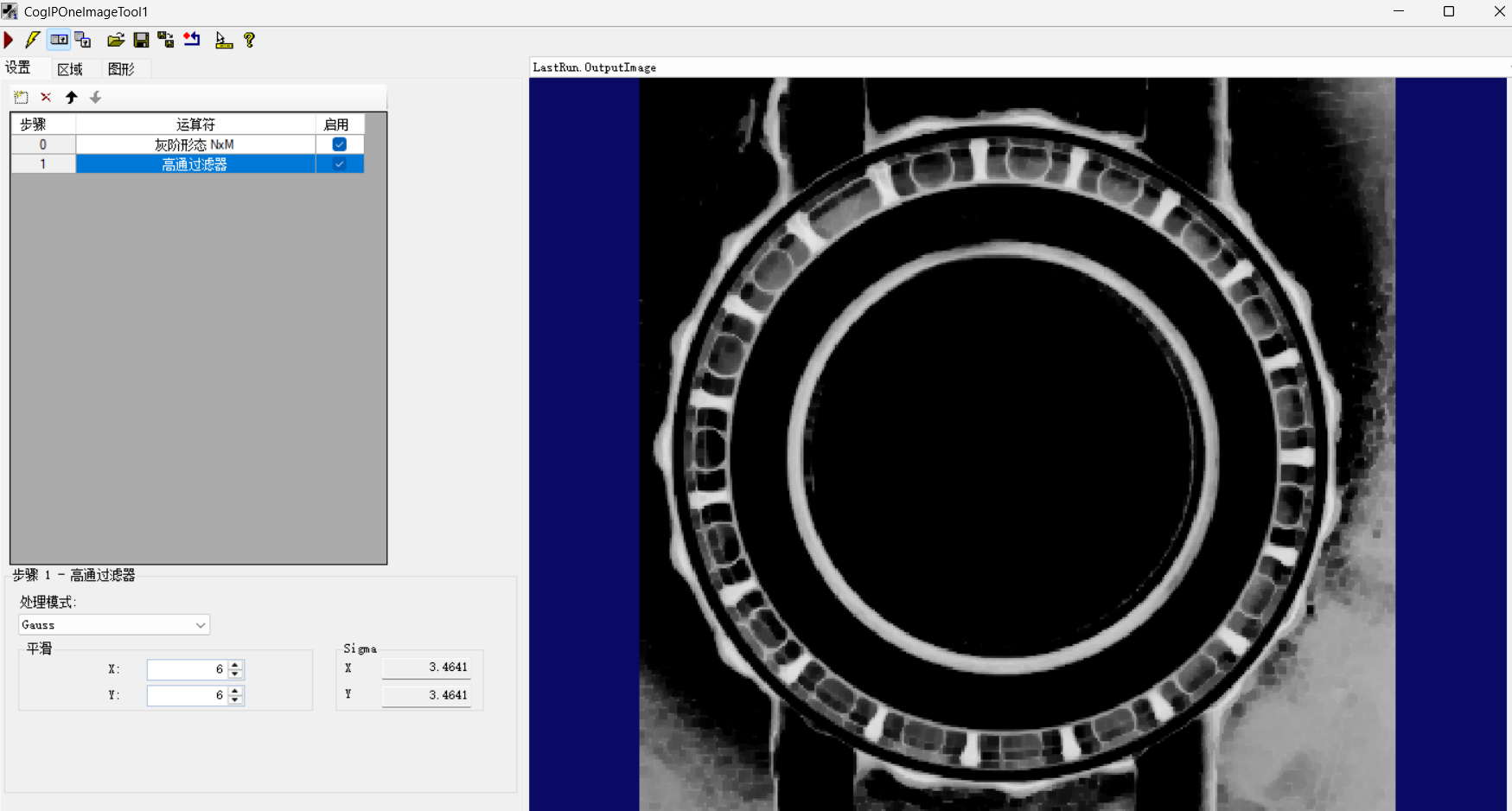

- 1.图像预处理:使用CogIPOneImageTool对图像进行灰度化、去噪等预处理操作,以提高后续处理的准确性。

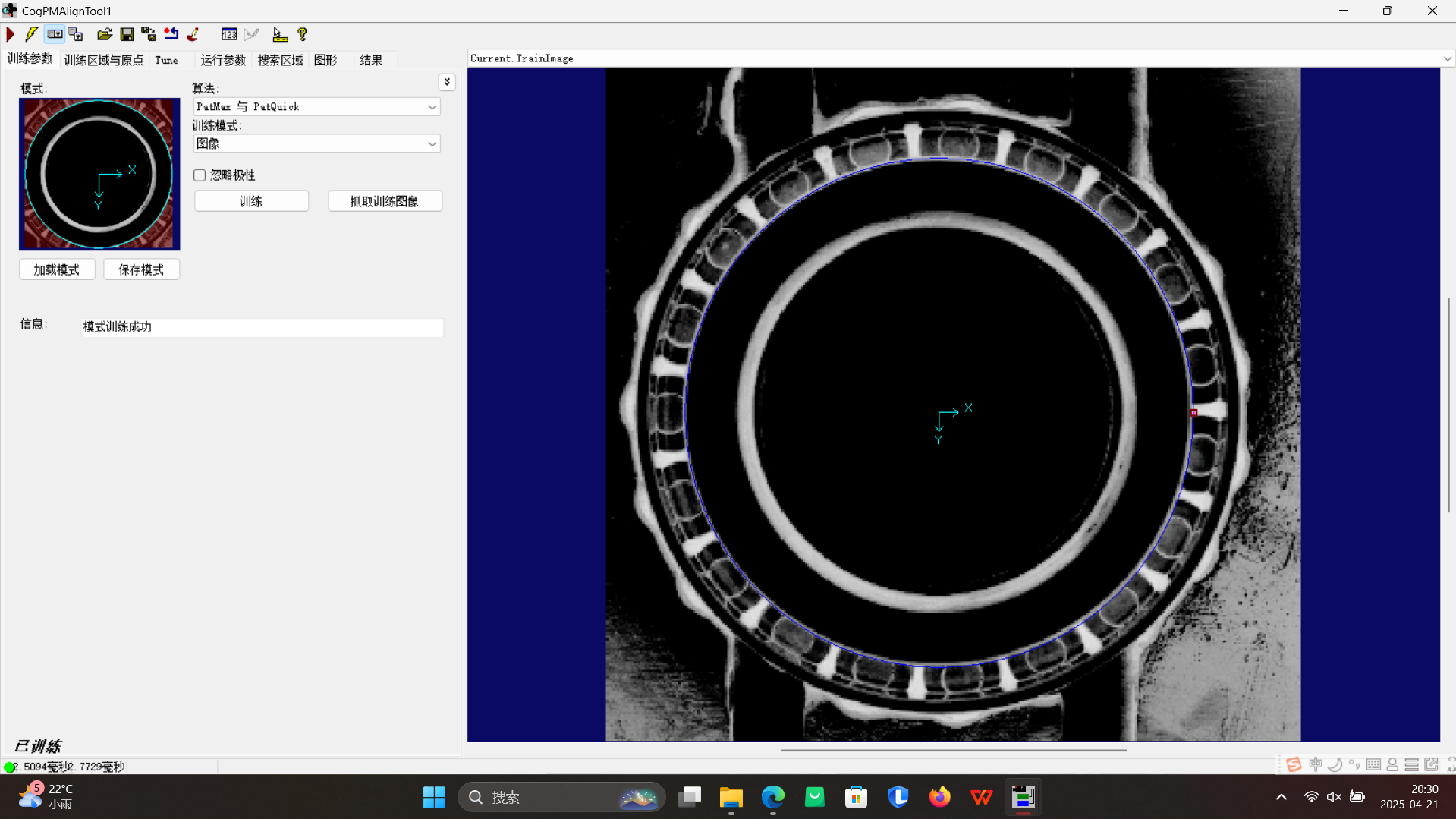

- 2.特征提取:使用CogPMAlignTool提供的工具提取轴承的概念建特征

- 3.图像校正: 使用CogFixtureTool,并把上面CogPMAlignTool找到的GetPose()传入进行位置矫正

- 4.圆展开: CogFindCircleTool找圆并通过找到的圆心坐标对CogPolarUnwrapTool的圆心赋值将图像从笛卡尔坐标系转换到极坐标系

- 5.模板匹配: 对展开后的图像进行模板匹配,匹配圆珠,没有匹配的地方则缺少,通过代码显示出来,并映射到原图中

- 6.完整代码展示

- 结论

项目概述

我们需要对下面轴承的缺珠情况进行检测,并且把缺珠的位置在图像上标记出来,效果如下:

思路以及解题过程

1.图像预处理:使用CogIPOneImageTool对图像进行灰度化、去噪等预处理操作,以提高后续处理的准确性。

2.特征提取:使用CogPMAlignTool提供的工具提取轴承的概念建特征

3.图像校正: 使用CogFixtureTool,并把上面CogPMAlignTool找到的GetPose()传入进行位置矫正

4.圆展开: CogFindCircleTool找圆并通过找到的圆心坐标对CogPolarUnwrapTool的圆心赋值将图像从笛卡尔坐标系转换到极坐标系

5.模板匹配: 对展开后的图像进行模板匹配,匹配圆珠,没有匹配的地方则缺少,通过代码显示出来,并映射到原图中

6.完整代码展示

#region namespace imports

using System;

using System.Collections;

using System.Collections.Generic;

using System.Drawing;

using System.IO;

using System.Windows.Forms;

using Cognex.VisionPro;

using Cognex.VisionPro.ToolBlock;

using Cognex.VisionPro3D;

using Cognex.VisionPro.ImageProcessing;

using Cognex.VisionPro.PMAlign;

using Cognex.VisionPro.CalibFix;

using Cognex.VisionPro.Caliper;

#endregionpublic class CogToolBlockAdvancedScript : CogToolBlockAdvancedScriptBase

{#region Private Member Variablesprivate Cognex.VisionPro.ToolBlock.CogToolBlock mToolBlock;#endregionCogGraphicCollection col = new CogGraphicCollection();/// <summary>/// Called when the parent tool is run./// Add code here to customize or replace the normal run behavior./// </summary>/// <param name="message">Sets the Message in the tool's RunStatus.</param>/// <param name="result">Sets the Result in the tool's RunStatus</param>/// <returns>True if the tool should run normally,/// False if GroupRun customizes run behavior</returns>public override bool GroupRun(ref string message, ref CogToolResultConstants result){// To let the execution stop in this script when a debugger is attached, uncomment the following lines.// #if DEBUG// if (System.Diagnostics.Debugger.IsAttached) System.Diagnostics.Debugger.Break();// #endifcol.Clear();CogPMAlignTool pm = mToolBlock.Tools["CogPMAlignTool2"] as CogPMAlignTool;CogPolarUnwrapTool Polar = mToolBlock.Tools["CogPolarUnwrapTool1"] as CogPolarUnwrapTool;//声明一个列表 用来储存X坐标List<double> listX = new List<double>();// Run each tool using the RunTool functionforeach(ICogTool tool in mToolBlock.Tools)mToolBlock.RunTool(tool, ref message, ref result);double y = 0,yTotal = 0;for(int i = 0 ; i < pm.Results.Count;i++){//将x坐标数据 添加到列表中listX.Add(pm.Results[i].GetPose().TranslationX);yTotal += pm.Results[i].GetPose().TranslationY;}//Y平均值y = yTotal / pm.Results.Count;//排序listX.Sort();//找缺陷的 比较逻辑for(int i = 0; i < listX.Count - 1;i++){if(listX[i+1] - listX[i] > 60){double x = (listX[i + 1] + listX[i]) / 2;double xIN,yIN;Polar.RunParams.GetInputPointFromOutputPoint(Polar.InputImage, Polar.Region, x, y, out xIN, out yIN);col.Add(CreateCircle(xIN,yIN));}}//第一个缺失if(listX[0]>40){double x = listX[0] - 40;double xIN,yIN;Polar.RunParams.GetInputPointFromOutputPoint(Polar.InputImage, Polar.Region, x, y, out xIN, out yIN);col.Add(CreateCircle(xIN,yIN));}//最后一个缺失if(listX[listX.Count-1] < 750){double x = listX[listX.Count-1] + 40;double xIN,yIN;Polar.RunParams.GetInputPointFromOutputPoint(Polar.InputImage, Polar.Region, x, y, out xIN, out yIN);col.Add(CreateCircle(xIN, yIN));}return false;}public CogCircle CreateCircle(double x,double y){CogCircle c = new CogCircle();c.CenterX = x;c.CenterY = y;c.Radius = 10;c.LineWidthInScreenPixels = 4;c.Color = CogColorConstants.Red;return c;}#region When the Current Run Record is Created/// <summary>/// Called when the current record may have changed and is being reconstructed/// </summary>/// <param name="currentRecord">/// The new currentRecord is available to be initialized or customized.</param>public override void ModifyCurrentRunRecord(Cognex.VisionPro.ICogRecord currentRecord){}#endregion#region When the Last Run Record is Created/// <summary>/// Called when the last run record may have changed and is being reconstructed/// </summary>/// <param name="lastRecord">/// The new last run record is available to be initialized or customized.</param>public override void ModifyLastRunRecord(Cognex.VisionPro.ICogRecord lastRecord){foreach(ICogGraphic g in col){mToolBlock.AddGraphicToRunRecord(g, lastRecord, "CogIPOneImageTool1.InputImage", "");}}#endregion#region When the Script is Initialized/// <summary>/// Perform any initialization required by your script here/// </summary>/// <param name="host">The host tool</param>public override void Initialize(Cognex.VisionPro.ToolGroup.CogToolGroup host){// DO NOT REMOVE - Call the base class implementation first - DO NOT REMOVEbase.Initialize(host);// Store a local copy of the script hostthis.mToolBlock = ((Cognex.VisionPro.ToolBlock.CogToolBlock)(host));}#endregion}结论

通过上述步骤和控件的使用,可以实现对轴承的缺陷检测。代码中使用了Cognex VisionPro工具进行特征提取和缺陷识别,并在图像上标记缺陷位置。项目可以根据实际需求进行扩展和优化